Part 1: Material Selection For Chemical Process Equipment

페이지 정보

본문

316LSS for structural applications where Ti larger energy and lower weight factor into the equipment (e.g., tanks). 50% of Titanium world use. Grade 7 Ti is comparable in properties to Grade 2 but has interstitial palladium (Pd), making it probably the most corrosion resistant of all Ti alloys. Grade 2 Ti. Some nitric acid functions are one instance the place stainless steels (304LSS in particular) present superior corrosion resistance over pure Ti. In surface ending, copper bussing (sometimes C11000 Digital Robust Pitch - ninety nine.9% Cu) is broadly used above tanks for electrified processes. Half 1 (Metals), Half 2 (Plastics), Half three (Different Materials), and Half 4 (Liners & Coatings) provided overviews of the broad range of supplies obtainable for different chemical process equipment applications. Part 5 (Paint & Powder Coating) overviewed choice of paint and powder coatings for process gear and course of system/space supplies.

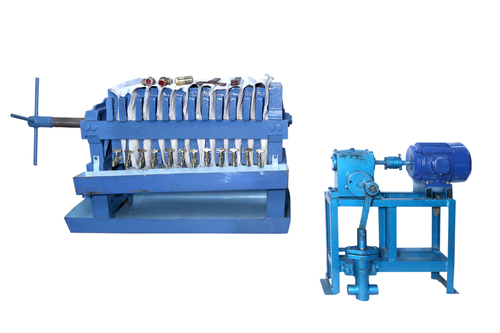

Suitable for driving remote digital indicators and chart recorders. Meals processing, pulp and paper and chemical processing industries served. Customized manufacturer of chemical process equipment made from fiberglass strengthened plastic and polyethylene. Varied capabilities embrace fabrication, engineering, transporting, filament wound, contact molded, hand lay up and turnkey methods integration. Meets ASME RTP-1, ASTM D4097 and ASTM D3299 requirements. A cutting-edge exhibit corridor hosts a whole bunch of main corporations from the oil and gas, petrochemical, power, pumping and turbomachinery industries. Firms show full-size tools and current advancements in expertise and rising industry tendencies. Finally, countless networking opportunities pervade the occasion, making TPS 2023 an event you can’t afford to overlook. One other factor that limited the capabilities of the older plate and body presses is they had been typically restricted to a lot decrease feed pressures of 80 to 125 per square inch (psi). As a result of vast use in past many years of the older fashion plate and body design, it is still fairly frequent to hear people name newer presses by the outdated identify of ? The plate and body filter press is a kind of separation equipment broadly used in industrial manufacturing. Filter Plates: These are the primary parts of the filter press. They're flat, rectangular plates with a central gap, often with filter cloths attached. Filter Frames: Frames surround the filter plates and supply assist. They even have a central gap that aligns with the outlet in the filter plates. Hydraulic System: Many fashionable plate and body filter presses use a hydraulic system to apply stress to the plates, squeezing the Best membrane filter plate in india cake between them for higher filtration.

Producer of standard and customized heavy/medium obligation portable, high capability industrial and gear/belt-pushed side entry mixers for chemical processing applications. Mixer configurations embrace mounts, drives, motors, impellers, tanks, wetted components, tie rods and pipe legs. Options differ relying upon model, including stainless steel or high energy aluminum housings, oversized driveshafts, bearings, flexible output couplings, shut-off collars and optionally available flush ports. Manufacturer of commonplace and custom chemical process equipment including mixing, mixing and coating equipment. Products embrace drum blenders, rotary mixers, rotary drum blenders, powder mixers, batch coaters and batch mixers. DS concentrations above 95% have been reported from pilot trials carried out below acceptable operating circumstances utilizing this expertise (Abu-Orf et al, 2007), with the cake dryness increasing with elevated operational cycle time as with the standard FP. These results relate to an unthickened thermophilic anaerobically digested sludge starting material, implying that dewatering and drying of raw sludges will be carried out in a single stage.

- 이전글단독] 안우진 변호인 백성문 변호사, "공중파 보도, 정확한 근거 제시해달라" 24.06.14

- 다음글Diyarbakır Ofis Escortlarının Faydalarını Keşfedin 24.06.14

댓글목록

등록된 댓글이 없습니다.